- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

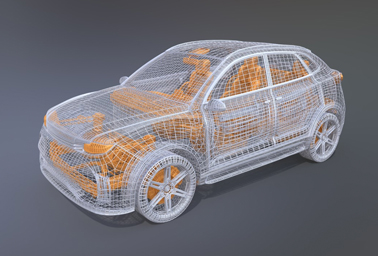

Aluminium or steel moulds for your plastic injections?

By Julien STOESS

Temps de lecture : 2 minutes /

Plastic injection molding uses two main types of mold. Aluminum molds and steel molds.

In this article, we’ll explore the advantages and differences of each method, to help you choose the best solution for your plastic injection project.

Advantages of aluminum molds :

Cost:

The manufacturing process for aluminum molds is faster. The density of aluminum (2.7) is much lower than that of steel (7.8). As aluminum is softer, it is easier to machine. Overall production costs are therefore reduced.

Thermal conductivity :

Aluminum has excellent thermal conductivity, which means it dissipates heat faster than steel. This means shorter cooling times during plastic injection molding. This speeds up production cycles and increases overall efficiency.

Lightweight and easy to machine:

Aluminum is a lightweight material, making molds easier to manufacture and handle. Its light weight also enables quicker and easier mold adjustments should the need arise.

Lead times:

Thanks to aluminum’s malleability, aluminum molds can be machined faster than steel molds. This reduces lead times and means that plastic parts can be brought to market more quickly.

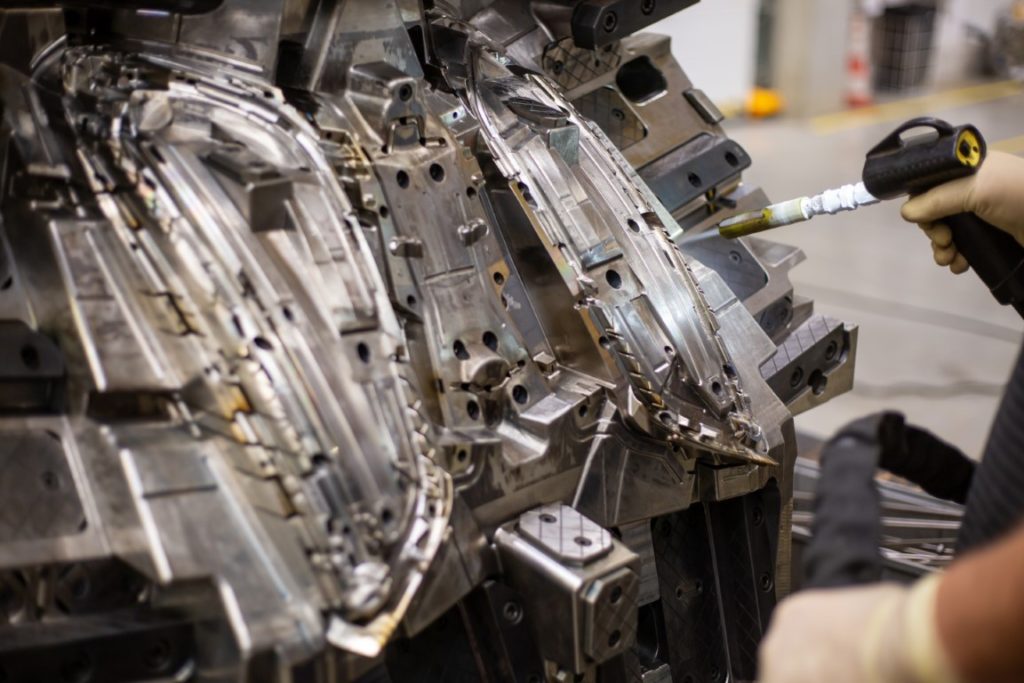

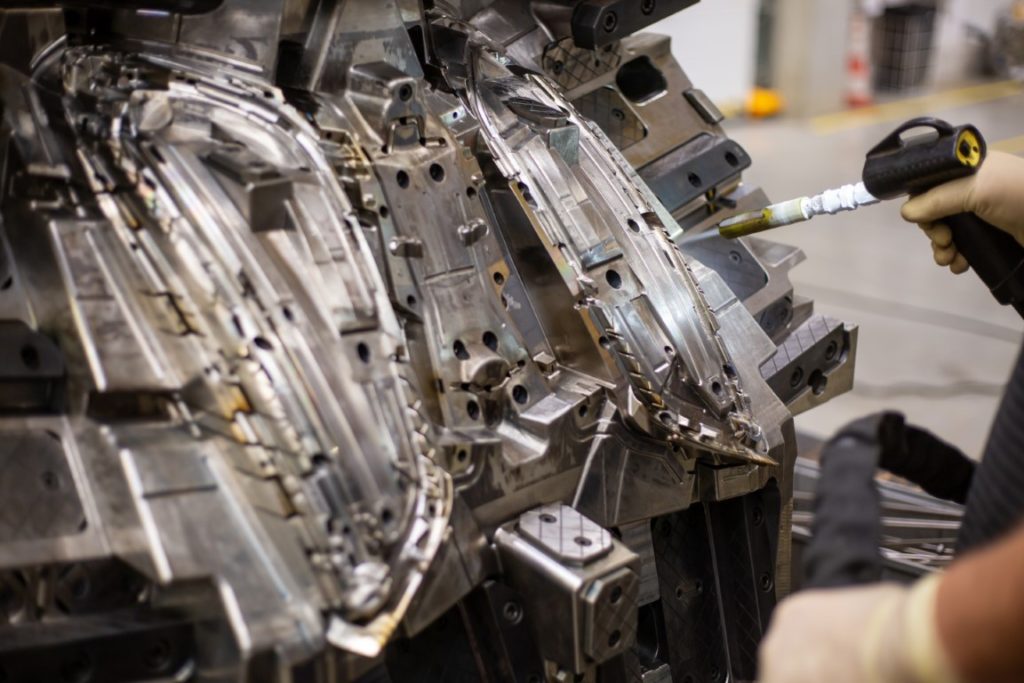

Advantages of steel moulds :

Durability and longevity:

Steel is a durable, wear-resistant material. It is therefore the preferred choice for applications requiring long mold life. Steel molds can withstand intensive production cycles and are more resistant to mechanical impacts.

Heat and pressure resistance:

Steel offers better heat and pressure resistance than aluminum. It is better suited to applications requiring high-temperature production conditions or higher plastic injection pressure.

Dimensional tolerances :

Steel molds offer superior long-term stability, enabling tighter dimensional tolerances to be maintained for plastic parts. This is particularly important for industries with precise requirements, such as automotive or medical, cosmetics, luxury goods, industrial or even aerospace.

Material flexibility:

Steel molds enable us to work with a wider range of materials, including technical materials and special resins. This offers greater flexibility in terms of material choice to meet specific application requirements.

In conclusion, aluminum molds offer advantages such as reduced costs, shorter lead times, high thermal conductivity and ease of machining. Steel molds offer increased durability, resistance to heat and pressure, tight dimensional tolerances and greater material flexibility. The choice between the two will depend on your project’s technical specifications, desired mold life, and precision requirements.

MDP TEAM is at your disposal to meet your prototyping and production needs in small or medium production runs. We are fully committed to listening carefully to your projects and finding customized solutions to make them a reality.

If you have any questions or a project in mind, please fill in the contact form. We’ll get back to you within 24 hours.

OUR CERTIFICATIONS

& LABELS >

Copyright © MDP TEAM