- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

- The Group

- Project support

- Our technologies

- The Activity

Discover more than 20 years of expertise

choosing your market >

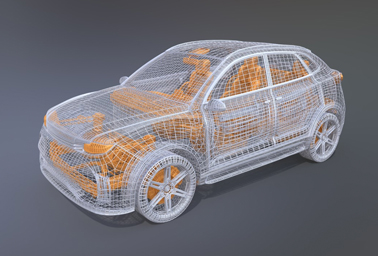

Prototype good material

Located in DAMPIERRE in the JURA (39), our company MDP – Moule Design Prototype realizes the design of your good material prototype for your small and medium series.

Aluminum: a reliable solution for your good material prototypes

For the realization of prototypes, the aluminum mold is a fast, economic and reliable solution. Indeed, to realize large series or even very large series, it is advisable to carry out preliminary tests. To do this, we use the aluminum mold to inject your prototype good material. It is faster to implement and for low investment costs.

Of course, the steel mold will have a longer life but it is more expensive and the realization times are much longer.

Established in France and heir to a tradition of plastics processing, MDP is referenced by major national and international players and subcontractors. Its know-how is exported year after year outside France. The quality of its aluminum molds makes it a first-rate player on the plastic injection and good material prototype scene.

Quality and strength: aluminum molds are gaining ground on steel

It is obvious that aluminum will not replace steel. However, techniques and technology are gradually evolving in recent years. The results that we have on our tests of resistance and longevity are better. The aluminum mold is now THE solution for the realization of plastic injections in small and medium series.

What is a “good material” prototype ?

MDP has become a specialist in good material prototypes thanks to its expertise in aluminum and steel molds. The MDP TEAM group is your development center for the industrialization of your plastic and metal-plastic parts. You can also rely on us for the assembly of your finished and semi-finished products.

The good material prototype is made from an aluminum mold in a very short time thanks to our technological excellence. The aluminum mold used for the plastic injection of the prototype is then machined and assembled to allow its mechanical validation. The good material prototype is a prototype with the same qualities as an injected part but with a short production time and lower investment.

OUR CERTIFICATIONS

& LABELS >

Copyright © MDP TEAM